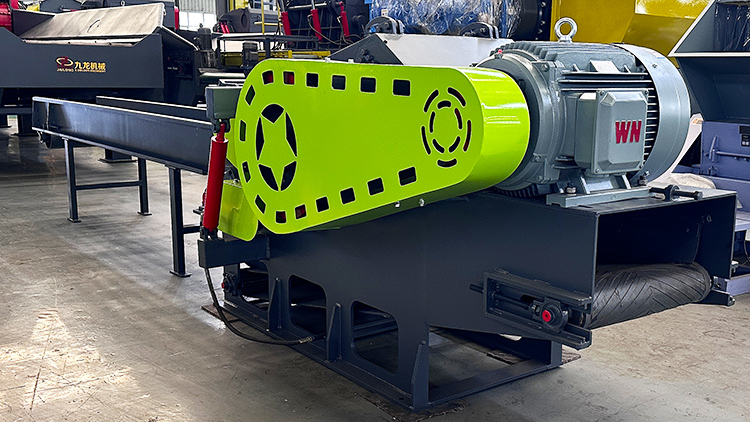

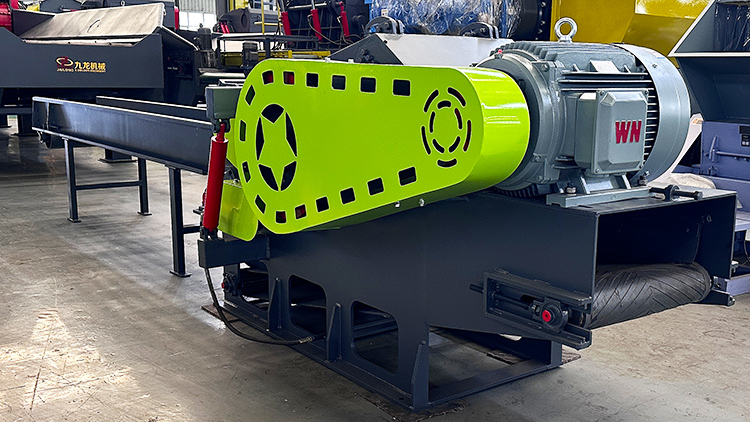

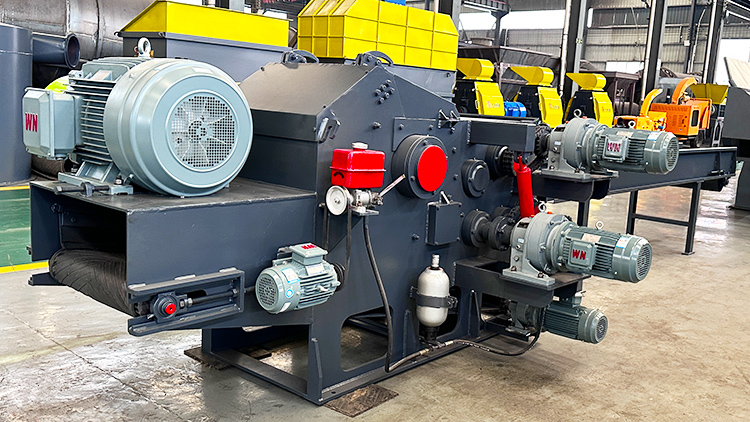

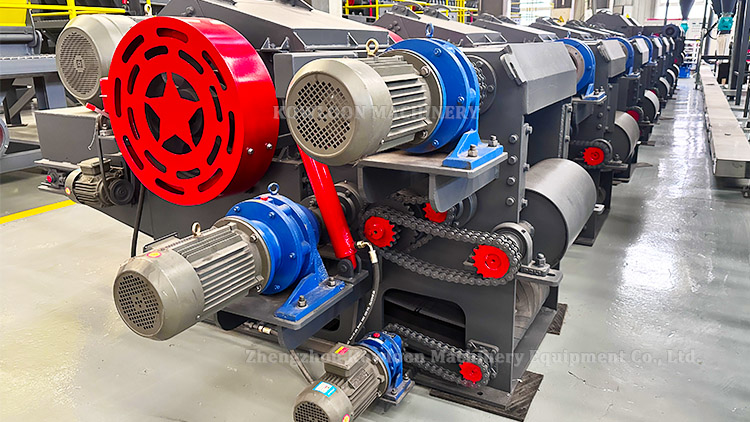

Drum Wood Chipper is a special equipment for producing wood chips, places an indispensable role in the wood processing industry. The wood chips produced by Kowloon Machinery Wood Chipper are in good shape, high quality, uniform length and thickness, and can be used in paper mill, power plant, pellet factory, boiler factory, etc.

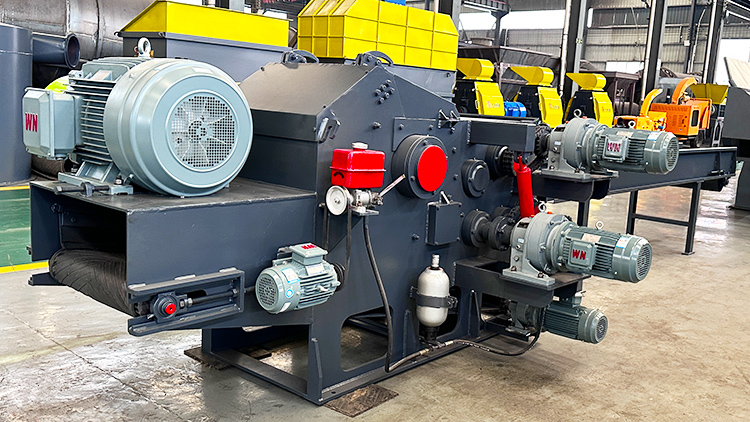

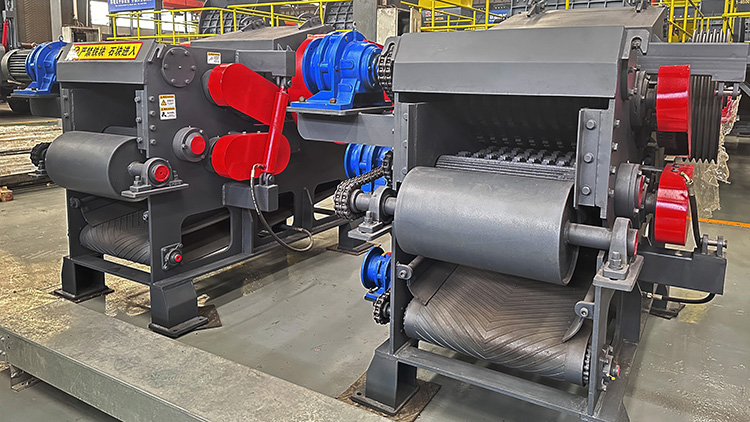

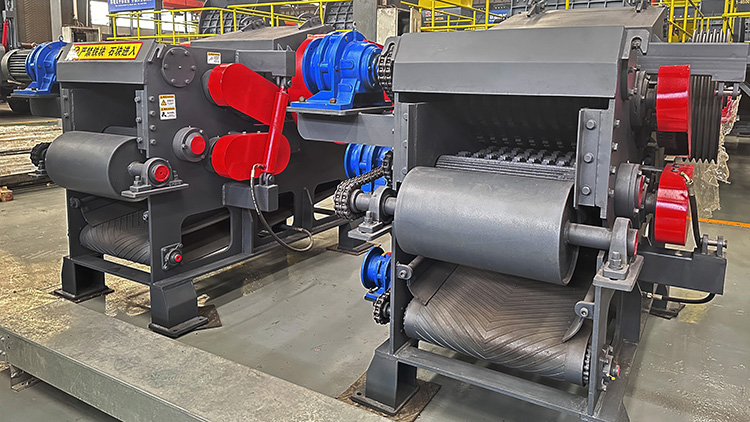

Drum Wood Chipper is composed of a machine base, knife rotor, feeding rollers, feed and discharge system, hydraulic system and other parts. The body of drum chipper made of high strengthen steel, the moving knives on rotor could be 2 knives, 3 knives, 4 knives. The moving knife fixed by high strength bolts and press board; hydraulic system helps chipper has ability to process different diameter materials.

Drum Wood Chipper can process all kinds of wood and biomass materials such as tree logs, trunks, branches, twigs, bamboo, sugarcane, slats, planks, reed stalks, timber, waste wood, etc.

Tree Logs

Branches

Bamboo

Timber Waste

Wood Waste

1. Compact structure, simple operation, wide application for wood materials chipping and biomass materials processing.

2. Adopting the double roller feeding system, has a higher efficiency than the common one.

3. The chipper body is made of high strength steel, firm, shock-resistant, with less noise.

4. A series of screen for choice, can process wood chips with a variety of size and thickness for different requirements.

5. Special design and reliable blades layout, works more efficiently. The wood chips is of even length and uniform thickness.

6. With the hydraulic buffer system, the maintenance of the chipping machine is simple.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

|

Model |

JLBX216 |

JLBX218 |

|

Infeed size (H*W) |

230x590mm |

300x680mm |

|

Process range |

≤φ230mm |

≤φ300mm |

|

Moving blade |

2/3/4 blades |

2/3/4 blades |

|

Rotary speed |

590 rpm |

650 rpm |

|

Main motor |

55kw |

90-110kw |

|

Feeder motor |

4kw+4kw |

5.5kw+5.5kw |

|

Hydraulic motor |

1.5kw |

1.5kw |

|

Feeding conveyor motor |

3kw |

4kw |

|

Weight |

5030kg |

7000kg |

|

Dimensions |

1800*1900*1210mm |

2200*2150*1500mm |