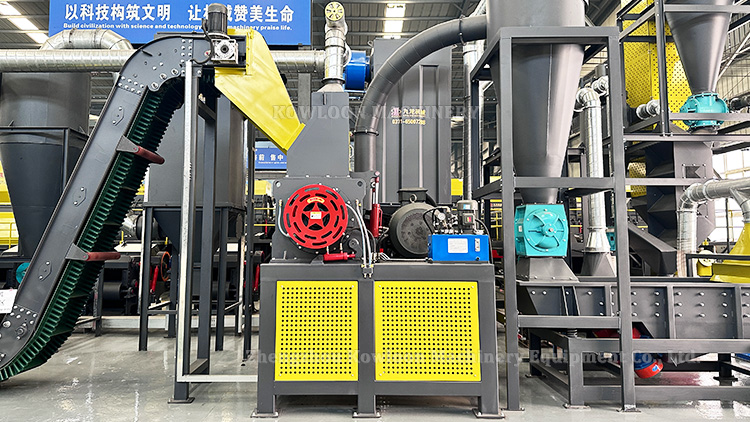

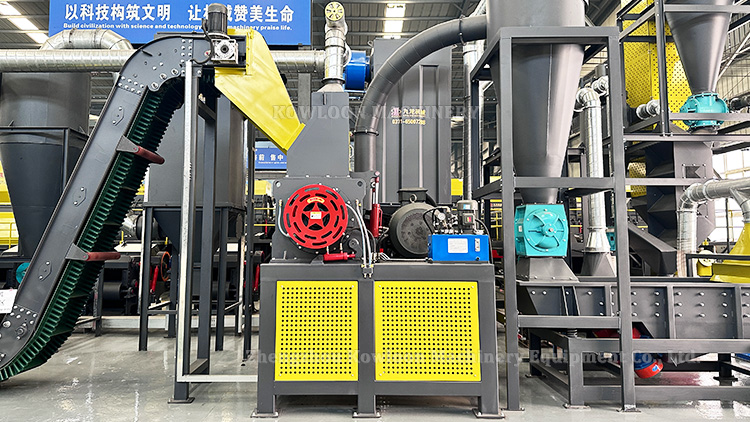

Rubber granulator is specially designed for rubber granulation in the rubber recycling line as the third step process. The first and second steps were able to shred the tires into 10-20mm rubber chips, and then the granulator could further grind them into 1-7mm rubber crumb. The outlet size required can be adjusted, as there are different sizes of screens available to ensure more flexible production. The final product after our rubber granulator will be 99.9% rubber crumb without fiber and wire.

Our granulator also can be used for waste plastic, paper and cardboard. Different blades are suitable for different materials to meet your production needs.

Waste bicycle tires, electric vehicle tires, motorcycle tires, tricycle tires, car tires, bus tires, off-road vehicle tires, agricultural and forestry machinery tires, light truck tires, engineering machinery tires, industrial vehicle tires, rickshaw tires, special vehicle tires, aviation tires and other waste tires and other rubber products.

Waste Tire

Truck Tire

Bus Tire

Waste Rubber Products

1. The advanced blade design is energy-efficient, reducing heat and wear, resharpenable and reusable.

2. The rotor is constructed of hardened steel and every exposed area inside the cutting chamber is fitted with a replaceable wear liner.

3. The main bearings are located on the exterior of the machine eliminating any chance of contamination.

4. The blades and screens are easily inspect and replace through hydraulically powered access doors.

|

Model |

JLSP800 |

JLSP1000 |

JLSP1200 |

JLSP1500 |

|

Main motor |

55kw |

75kw |

90kw |

110kw |

|

Rotor diameter |

600mm |

600mm |

700mm |

700mm |

|

blade |

Made of H13, solid blade |

|||

|

Hydraulic station |

2.2kw |

2.2kw |

3kw |

3kw |

|

Self-discharge belt conveyor |

2.2kw |

2.2kw |

3kw |

3kw |

|

Screen hole size |

Dia.3-7mm |

|||

|

Dimensions |

3.35*1.65*2.95m |

3.25*1.85*2.95m |

2.7*2.05*3.45m |

2.7*2.4*3.45m |

As a professional manufacturer, Kowloon Machinery provide customized tire recycling solution depending on your requirements.

Through the whole process of intelligent automation, waste tires resource system realizes the high-value recycling of tires: the tire bead wires are precisely stripped with a tire debeader. Tires are crushed into 50-100mm by a double-shaft shredder, and then crushed into 10-20mm by a rubber rasper. The residual wire is completely separated by bipolar magnetic separations. Furthermore, the crushed rubber is processed into 1-7mm by a rubber granulator or 5-80 mesh by a grinder. There is ladder type air separator to remove fiber impurities, and a pulse dust removal system to achieve clean production. The entire system is monitored by a plc intelligent control center and has fault warning and linkage control functions.