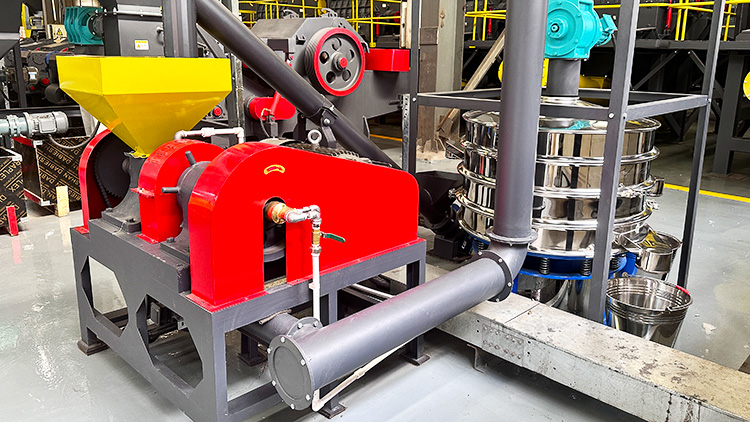

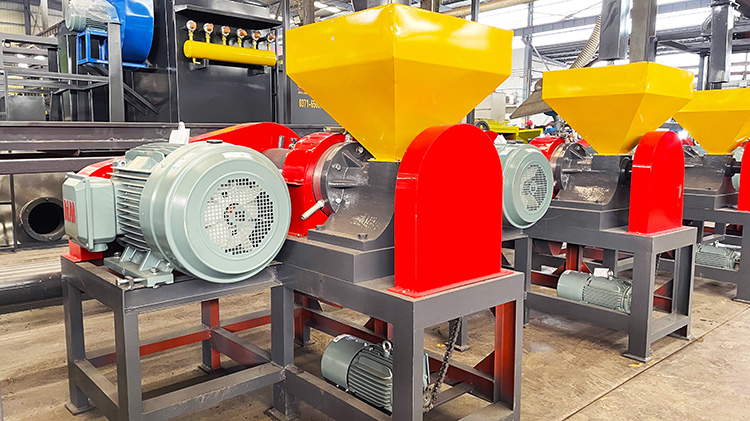

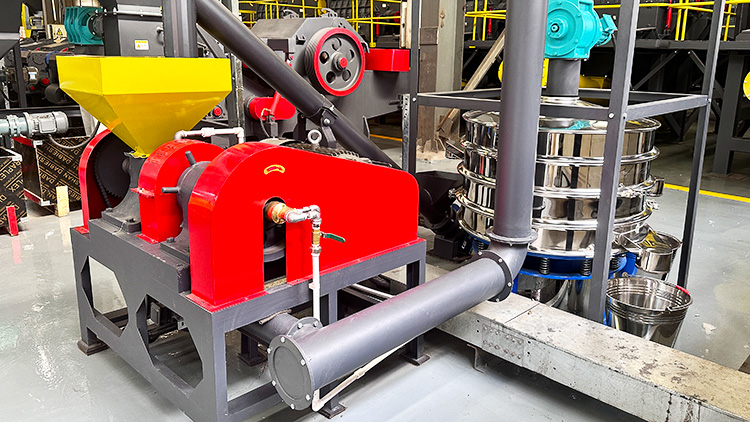

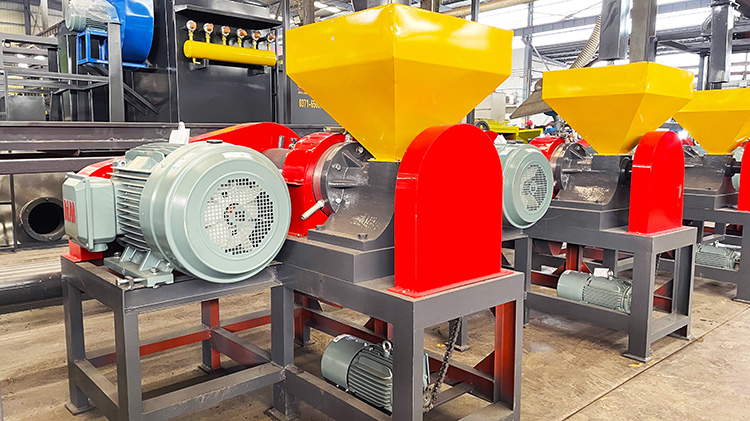

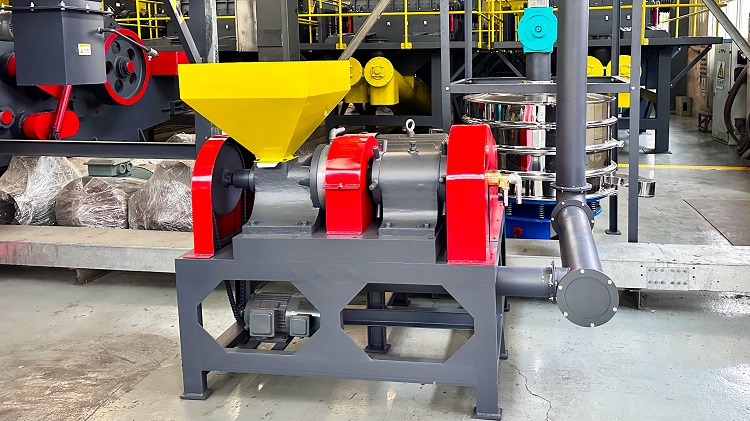

Rubber powder making machine is a disc mill, its function is to grind rubber granules into fine rubber powder. It is equipped with inner water cooling system to reduce working temperature, therefore it owns ability to work 24 hours at room temperature. Two-disc structure, adjustable clearance between discs, various powder sizes between 5-80 mesh can be obtained. The rubber powder produced can be used in building materials, rubber products and other fields.

Kowloon Machinery provides complete automatic line equipment for waste tire recycling solution.

√ Waste tires: car tires, truck tires, OTR tires, etc.

√ Waste rubber: used V belt, rubber mat, rubber products, etc.

Car Tire

Bus Tire

Truck Tire

Waste Rubber Products

1. Equipped with cyclone silo to collect product powder dust and realize dust-free working environment.

2. The discharging fineness can be adjusted according to customer needs.

3. Small size of equipment, high output, low noise, low energy consumption, simple operation, easy disassembly.

4. The obtained fine powder has numerous burrs and fractal powder surface, and is easy to combine with other colloids.

|

Model |

JLRM280 |

|

Capacity |

60-85kg/h |

|

Feeding material |

1-10mm rubber granules |

|

Output rubber powder |

30-120mesh |

|

Total Power |

28kw |

|

Temperature of working |

≤80℃ |

|

Dimension(L*W*H) |

1500*1000*1200mm |

|

Weight |

1000kg |

As a professional manufacturer, Kowloon Machinery provide customized tire recycling solution depending on your requirements.

Through the whole process of intelligent automation, waste tires resource system realizes the high-value recycling of tires: the tire bead wires are precisely stripped with a tire debeader. Tires are crushed into 50-100mm by a double-shaft shredder, and then crushed into 10-20mm by a rubber rasper. The residual wire is completely separated by bipolar magnetic separations. Furthermore, the crushed rubber is processed into 1-7mm by a rubber granulator or 5-80 mesh by a grinder. There is ladder type air separator to remove fiber impurities, and a pulse dust removal system to achieve clean production. The entire system is monitored by a plc intelligent control center and has fault warning and linkage control functions.