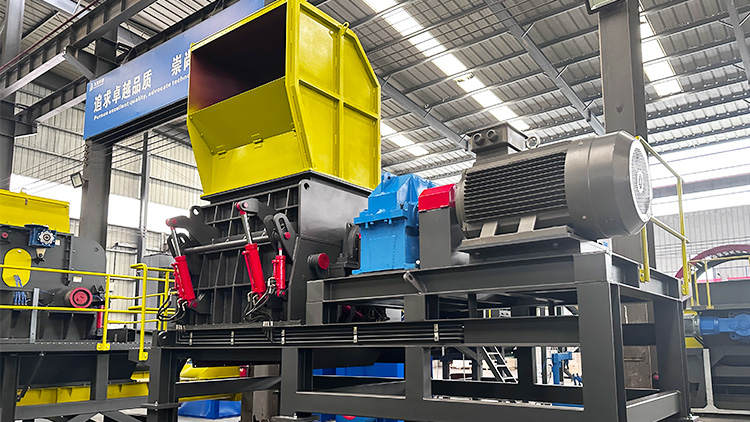

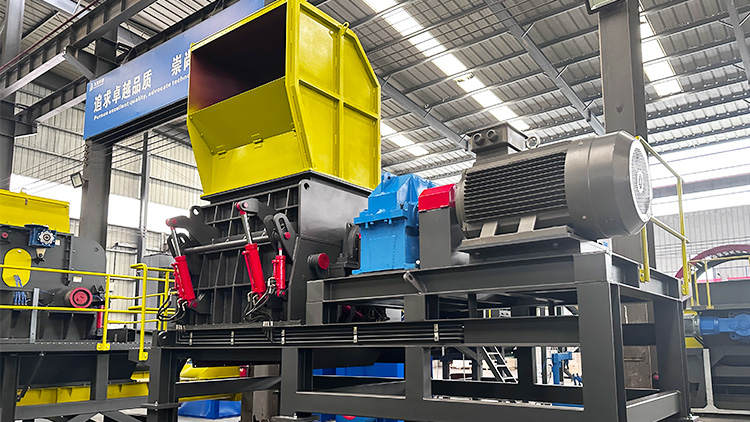

Tire Rasper is also called tire steel wire separator, it is designed to remove steel wire from the rubber tires with claw blade with teeth, and separate them via magnet separator above discharge conveyor, steel wire separating purity 98%. Raspers are a necessary piece of equipment for tire recycling, crushing rubber even further for future processing. It also can process maximum 300x300mm rubber chips into 10-15mm granules.

We offer customized tyre recycling solutions depending on your requirements for input tyre type, production capacity, and output size/purity depending on your needs. Each tire recycling equipment is heavy duty and extremely durable, built for processing tire rubber and other materials for a long time.

Waste bicycle tires, electric vehicle tires, motorcycle tires, tricycle tires, car tires, bus tires, off-road vehicle tires, agricultural and forestry machinery tires, light truck tires, engineering machinery tires, industrial vehicle tires, rickshaw tires, special vehicle tires, aviation tires and other waste tires and other rubber products.

Car Tire

Truck Tire

Bus Tire

Waste Rubber Products

1. Frequency conversion control, automatic stop feeding when overload.

2. Double-edged blades, each blade could be used twice. Blades made of H13, high hardness, anti-wear , longer working life.

3. Hydraulic assistant system for helping open and changing screen and blade maintenance.

4. With pulse dust collector and enclosed feed hopper, low dust when work inside room.

|

Model |

JLRS800 |

JLRS1000 |

JLRS1200 |

JLRS1500 |

|

Main motor |

90kw |

110kw |

132kw |

160kw |

|

Feed particle size |

≤50mm |

≤50mm |

≤50mm |

≤50mm |

|

Mesh size |

Φ10-Φ15mm |

Φ10-Φ15mm |

Φ10-Φ15mm |

Φ10-Φ15mm |

|

End product size |

10-15mm |

10-15mm |

10-15mm |

10-15mm |

|

Working capacity |

500-750kg/hour |

750-1000kg/hour |

1000-1250kg/hour |

1250-1500kg/hour |

|

Moving knife quantity |

36 |

48 |

36 |

48 |

|

Dead knife quantity |

12 |

16 |

12 |

16 |

|

Dimension(L*W*H) |

1650*1700*2300mm |

2000*1750*2300mm |

2300*1770*2300mm |

2750*1800*2300mm |

|

Weight |

4800kg |

5200kg |

5600kg |

6000kg |

|

Feed conveyor (LxW) |

8000x650mm,4kw |

8000x800mm,4kw |

8000x1000mm,4kw |

8000x1200mm,4kw |

As a professional manufacturer, Kowloon Machinery provide customized tire recycling solution depending on your requirements.

Through the whole process of intelligent automation, waste tires resource system realizes the high-value recycling of tires: the tire bead wires are precisely stripped with a tire debeader. Tires are crushed into 50-100mm by a double-shaft shredder, and then crushed into 10-20mm by a rubber rasper. The residual wire is completely separated by bipolar magnetic separations. Furthermore, the crushed rubber is processed into 1-7mm by a rubber granulator or 5-80 mesh by a grinder. There is ladder type air separator to remove fiber impurities, and a pulse dust removal system to achieve clean production. The entire system is monitored by a plc intelligent control center and has fault warning and linkage control functions.