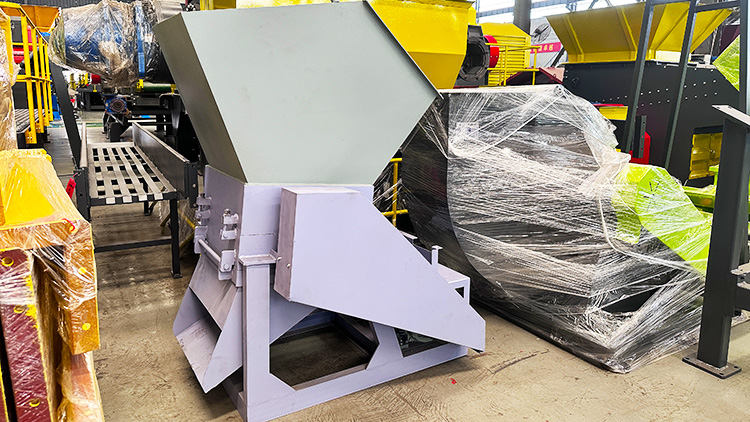

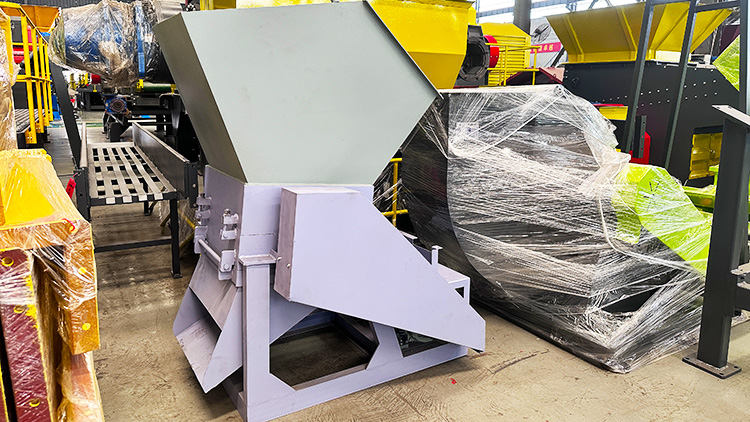

Product: Plastic Shredder/ Plastic Crusher/ Plastic Granulator

Raw Material: Plastic bottles, lumps, pipes, barrels, pallet, toy, tray, bumper, and PVC, PE, PP, ABS, PET, HDPE product waste, etc.

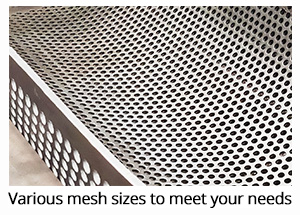

Plastic Granulator is a machine to crush plastic materials into small pieces, reduce the volume of plastic waste, making them easier to recycle or further process. It has high rotational speed and sharp blades which ensures smooth size reduction of plastic products in different forms. The outlet material is small and uniform pieces, it can also adjust the blade clearance and change the screen sieve to control the outlet material size.

Kowloon Machinery is a professional manufacturer of plastic shredder and granulator, free customized solution according to your needs. Contact us now to get the latest quotation!

1. Plastic Recycling Plants: Crushing PET bottles, PE/PP containers, and post-consumer plastic waste for further washing and pelletizing.

2. Packaging Industry: Handling defective products, film rolls, offcuts, and packaging trims for reuse.

3. Injection Molding Facilities: Reprocessing sprues, runners, and rejected molded parts to reduce material waste.

4. Blow Molding Factories: Recycling thick wall or hollow plastic products, including bottles and jugs.

5. Textile Industry: Processing plastic fiber waste, such as polyester scraps or yarn cones.

6. Automotive Industry: Breaking down bumpers, dashboards, and plastic panels during vehicle recycling.

Plastic Bottles

Plastic Pipes

Plastic Lumps

Plastic Buckets

Other Plastic Waste

1. Durable Steel Construction: The machine features a thickened steel plate shell and bracket, providing unmatched durability and stability.

2. High-Quality Blades: Stronger and wear-resisting, repeatedly sharpened when blunt and achieve using life.

3. Reasonable blade design: Staggered blades can decentralize working load when granulating to increase cutting efficiency.

4. High-Performance Motor: Equipped with a powerful motor for efficient, smooth and reliable operation.

5. High-Output Capability: Engineered to deliver high efficiency and high output, ensuring rapid processing of plastic materials.

6. Low Maintenance Operation: Low failure rate, less maintenance, reducing downtime and operational costs.

7. Specifically designed to crush plastic materials into granules, and small footprint.

Plastic shredder and plastic granulator are both key equipment in plastic recycling. Plastic shredder is adept at handling large-sized, tough plastics, breaking them down into smaller pieces which can then be further crushed by a plastic granulator to abtain flakes and fine particles.

1. Plastic Shredder

The function of plastic shredder the is to break large, hard or irregular plastic materials into smaller pieces (usually a few centimeters to more than ten centimeters) to prepare for subsequent processing (such as granulation, reprocessing). The characteristics of the materials it processes are: large volume, irregular shape, high hardness or strong toughness, and it is difficult to directly refine and process.

Applicable materials: Plastic barrels, pallets, sheets, pipes, containers, shells and plastic parts in waste home appliances, plastic components, bumpers, dashboards, seat frames of cars, mixed plastic scraps of different materials, plastics with metals and impurities.

2. Plastic Granulator

The function of the plastic granulator is to further process the initially crushed plastic fragments (or finer plastic waste) into uniform plastic particles (usually 5-15 mm in diameter), which can be directly used as raw materials for the production of new plastic products. The characteristics of the materials it processes are: small size (already broken), high purity (impurities need to be removed), and suitable for melt reshaping.

Applicable materials: Various plastic fragments, small plastic products, small plastic waste, injection molding/extrusion processing scraps, etc. after being processed by the shredder.

3. The relationship and difference between plastic shredder and plastic granulator:

Processing stage: The shredder is "rough processing", processing the original large pieces of materials; the granulator is "fine processing", processing the fine pieces after shredding, and outputting standardized particles.

Material size: The shredder inputs "large pieces/irregular materials" and outputs "fragments"; the granulator inputs "fragments/fine pieces" and outputs "small granules".

Application scenario: The shredder is often used for front-end crushing in the recycling process, and the granulator is used for granulation production at the back end, which is the core link of plastic recycling.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, plastic waste, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.