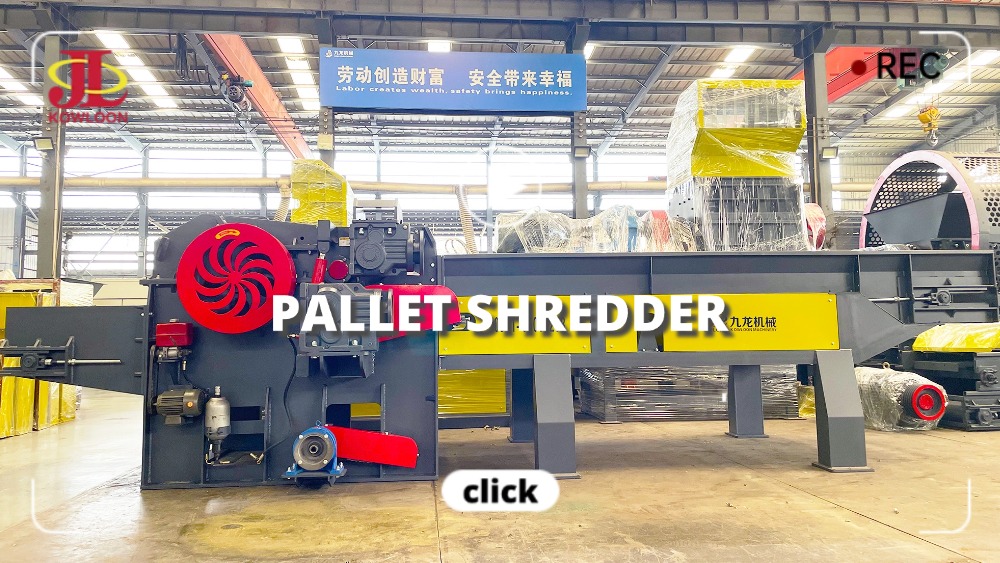

Pallet shredder is used to coarse crush large number of discarded pallets into small shreds, while output separate nails and other metal materials, the pure wood shreds go forward for further processing. Cause wood pallets often have metal objects such as nails and wires on them, which can only be crushed by pallet chipper.

Pallet shredder mainly consists of working platform, feeding roller and conveyor. The whole machine has integrated linkage control of conveying, feeding, pressing plate and crushing. In addition, various types of wood processing equipment can be customized according to customer requirements.

Pallet Shredder is especially designed for plywood sheet, boards, pallets, strips, furring, nailed wood tray, and other wood offcut wastes, which width up to 1.5m, thickness 3-15mm. It is widely used in wood processing factory, power station, wood board, wood furring and wood scraps recycle industry, plywood processing factory, etc.

Pallets

Wood Waste

Timber Waste

1. Use special blades with high hardness; meshing blades to crush the material thoroughly.

2. Hammer head made of unti-wear materials, long working life.

3. Has ability of processing nailed wood wastes and tiny steel mixed wooden wastes.

4. Reasonable price, simple structure and function, low noise, stable operation, safe and durable.

5. Low energy consumption, high output, good quality of crushed products, and low processing cost.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

|

Model |

JLXP400P |

JLXP800P |

JLXP1000P |

JLXP1380P |

JLXP1500P |

|

Width of feeding conveyor |

400mm |

800mm |

1000mm |

1380mm |

1500mm |

|

Feeding port size(WxH) |

400x100mm |

800x120mm |

1000x150mm |

1200x200mm |

1500x250mm |

|

Power of main motor |

22kw |

37-45kw |

55-75kw |

90kw |

90-132kw |

|

Power of feeding motor |

4kw*2 |

4kw*2 |

4kw*2 |

5.5kw*2 |

7.5kw*2 |

|

Conveying speed |

0.45m/s |

0.65m/s |

0.75m/s |

0.80m/s |

1.1m/s |

|

Feeding roller rotary speed |

650rpm |

|

|

|

|

|

Cutter shaft rotary speed |

680rpm |

|

|

|

|

|

Working capacity |

1-3ton/h |

3-8ton/h |

5-10ton/h |

7-15ton/h |

12-25ton/h |

|

Weight |

3000kg |

6000kg |

8000kg |

12000kg |

16000kg |