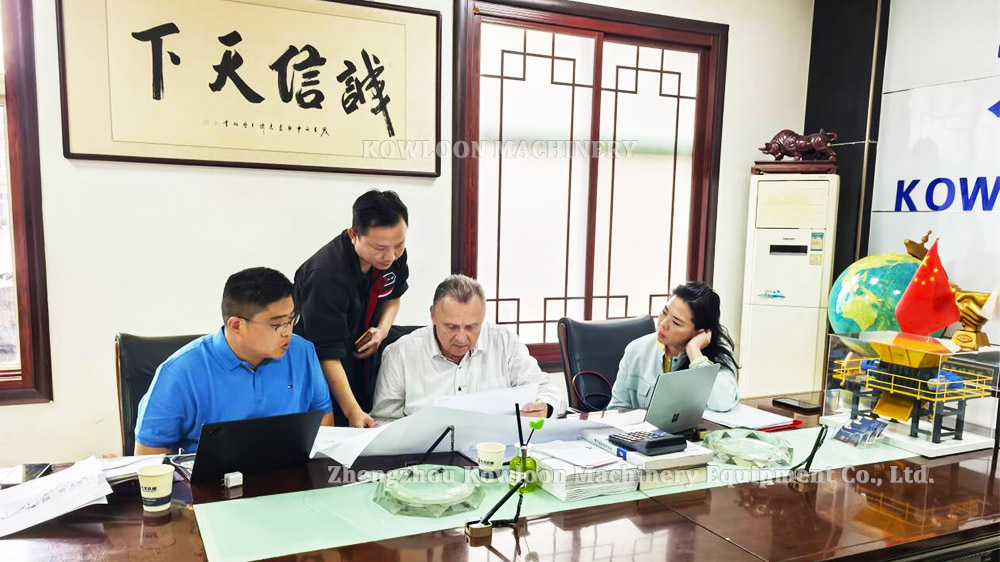

Recently, Czech customer visited our company to conduct an in-depth study of waste tire recycling solution. The customer plans to build an automatic tire recycling line with an output of 2 tons per hour this year. This visit focused on observing the full process test of our tire recycling line, from tire wire drawing, crushing, to efficient separation of steel wire and rubber granulation. We explained the whole process to the customer, which won the customer’s high recognition.

Finished product application industry:

√ Reclaimed Rubber

Crumb rubber can be widely used in reclaimed rubber to produce mats, pipes, cable, insulation materials, flame retardant materials, waterproof materials and other fields. Reclaimed rubber used together with natural rubber and synthetic rubber to effectively reduce the cost of raw materials.

√ Modified Asphalt

Fine rubber powder mixed with resin, high molecular polymer, admixture, etc. Roads, runways, playgrounds paved with modified asphalt have the advantages of being flat, non-slip, having good drainage, reducing noise and having low cost.

√ TDA (Tire Derived Aggregate)

TDA is a recyclable building material extracted from waste tires. As an engineering material substitute for traditional aggregates, it has the advantages of light weight, high permeability, strong thermal insulation, strong shock absorption ability and low cost.

√ TDF (Tire Derived Fuel)

The high calorific value of waste tires makes it a good alternative fuel for industries such as cement plants, power plants, and paper mills, with the advantages of low carbon emissions and low cost.

Interested customers are welcome to visit Kowloon Machinery, contact us immediately to make an appointment!