Biomass straw shredder is a specialized mechanical equipment used for processing agricultural waste such as rice straw, paddy straw, wheat straw. Biomass shredder achieves efficient and precise processing of materials such as straw, through the working principle of biaxial shearing and extrusion. The crushed material can be used as livestock forage and papermaking raw materials, as fuel for boiler, furnace or power plant.

Kowloon Machinery supply complete biomass straw recycling line with customized solution depend on your requirements. Contact us now for the best solution and price!

Biomass waste such as rice straw, wheat straw, paddy straw, corn stalks, peanut stalks, wheat stalks, soybean stalks, cotton stalks, sugarcane, tree bark, tree root, corn cob, palm leaves, EFB, coconut shells, green waste, wooden boards, etc.

Straw Round Bales

Straw Bales

Forage Grass

Corn Stalks

Soybean Stalks

Cotton Stalks

Palm EFB

Coconut Shell

Wood Waste

Green Waste

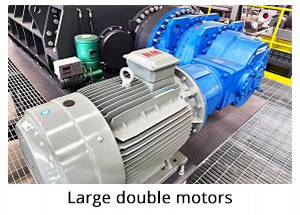

Our shredder is specially designed for shredding and recycling biomass waste. It features a dual-shaft design, equipped with high-strength blades and automatic feeding to ensure high efficiency and uniform output. Dual motor + Dual reducer drive system, low speed, high torque and strong tearing ability. It's a ideal equipment for biomass power plants, composting stations, pellet production lines, animal feeding, biomass coupled power plant, biogas power generation, biomass fuel, paper mill, etc.

The biomass waste recycling system consists of a double shaft shredder, chain plate conveyor, belt conveyor, drum screen, magnetic separator, baler, intelligent monitoring system, etc. It can process biomass raw materials into the required specifications according to needs. The system is equipped with pulse dust removal to reduce dust pollution, intelligent crushing efficiency is high, and can meet long-term stable operation. The finished materials can be packaged and sent to power plants, paper making plants or used in livestock farms according to user needs.

1. The motor of a well-known brand is selected as the electric drive, which can withstand long-term operation, is full of power, and operates stably, which can greatly improve work efficiency. The quality of the famous brand is guaranteed and can be used with confidence.

2. The use of planetary reducers can reduce the motor speed and increase the output torque. It has many advantages such as light weight, small size, high transmission efficiency, wide reduction range, high precision and low noise.

3. Tungsten carbide wear-resistant tools can effectively increase production and extend service life through laser cladding. Tools can also be repaired multiple times after wear, saving use costs.

4. Modular chassis. The chassis adopts mortise and tenon design and overall annealing process. Prestress caused by welding is avoided, and the mechanical strength of the chassis is high. The chassis is divided into upper and lower parts, which is convenient and quick to inspect and maintain.

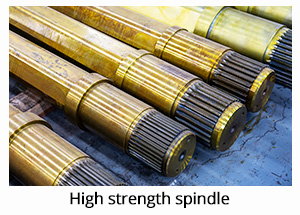

5. The inner hole of the tool and the main shaft adopt the hexagonal design, which has good torque transmission effect. The movable and fixed blades are combined, and the movable blade is detachable for easy replacement. It is made of imported high-alloy steel material with good wear resistance.

6. The spindle is made of high-strength alloy steel with good mechanical strength, strong fatigue and impact resistance, and adopts a hexagonal design to better ensure the transmission effect of torque and improve the good cooperation with the tool.

7. The PLC adopts Siemens centralized control, automatically detects reversal, and better protects the motor and tool.

Kowloon Machinery has 19 years of technology accumulation and specializes in the production of solid waste recycling equipment, such as biomass waste, waste tires, scrap metals, large waste, industrial waste, agricultural and forestry waste, etc., and provides targeted recycling solutions. Our products have obtained multiple patents and CE, ISO certifications. At present, our solid waste recycling projects cover Poland, Czech Republic, Romania, Russia, South Africa, Algeria, Brazil, Saudi Arabia and many other countries.

|

Model |

JLSS600 |

JLSS1000 |

JLSS1200 |

JLSS1500 |

JLSS2000 |

JLSS2600 |

|

Main shaft power |

4-15kw*2 |

4-30kw*2 |

4-37kw*2 |

4-45kw*2 |

4-90kw*2 |

4-160kw*2 |

|

Main shafe rotary speed |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

18-20rpm |

|

Working capacity |

2-5t/h |

5-10t/h |

6-15t/h |

8-18t/h |

10-25t/h |

25-60t/h |

|

Weight |

3000kg |

5000kg |

6000kg |

12000kg |

15000kg |

36000kg |

|

Conveyor motor power |

None |

None |

None |

4-3KW |

4-3kw |

4-3KW |

|

Number of cutter head |

20pcs*φ400 |

34pcs*φ400 |

42pcs*φ400 |

46pcs*φ550 |

50pcs*φ600 |

40pcs*φ720 |

|

Finished ships size |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

3-10cm |

|

Feeding tank size |

0.82*0.9m |

1.2*1m |

1.4*1m |

2*2m |

2.3*2m |

2.5*1.4m |

|

Dimension |

2.6*2*1.9m |

3*2*1.9m |

3.2*2*1.9m |

4*1.7*2.4m |

8*2.5*2.4m |

8.2*4.4*4.3m |